Steambending Wood

Many of the boat parts did not require steambending because they were long and flexible and were held in shape by the ribs. A few of the optional parts like the rear leg brace and the anchor support did require steambending. Since I did not plan to do a great deal of steambending work, I built a makeshift steam box and used a Gingery gas fired crucible furnace equipped with a Ron Reil burner to heat water in an old steel container.

In the photo below, you can see steam escaping from the particle board box. The box disintegrated after the last piece of wood was steamed. Obviously you should use solid wood for a more permanent steam box. Wood takes about 1 hour per inch of thickness to heat to the point where it will bend and hold a form. When you take the wood out of the box it has a strange feel to it. The best way that I can describe it, is that it feels like hard rubber. As soon as you remove it from the box, you have about a minute to bend it into the shape that you want.

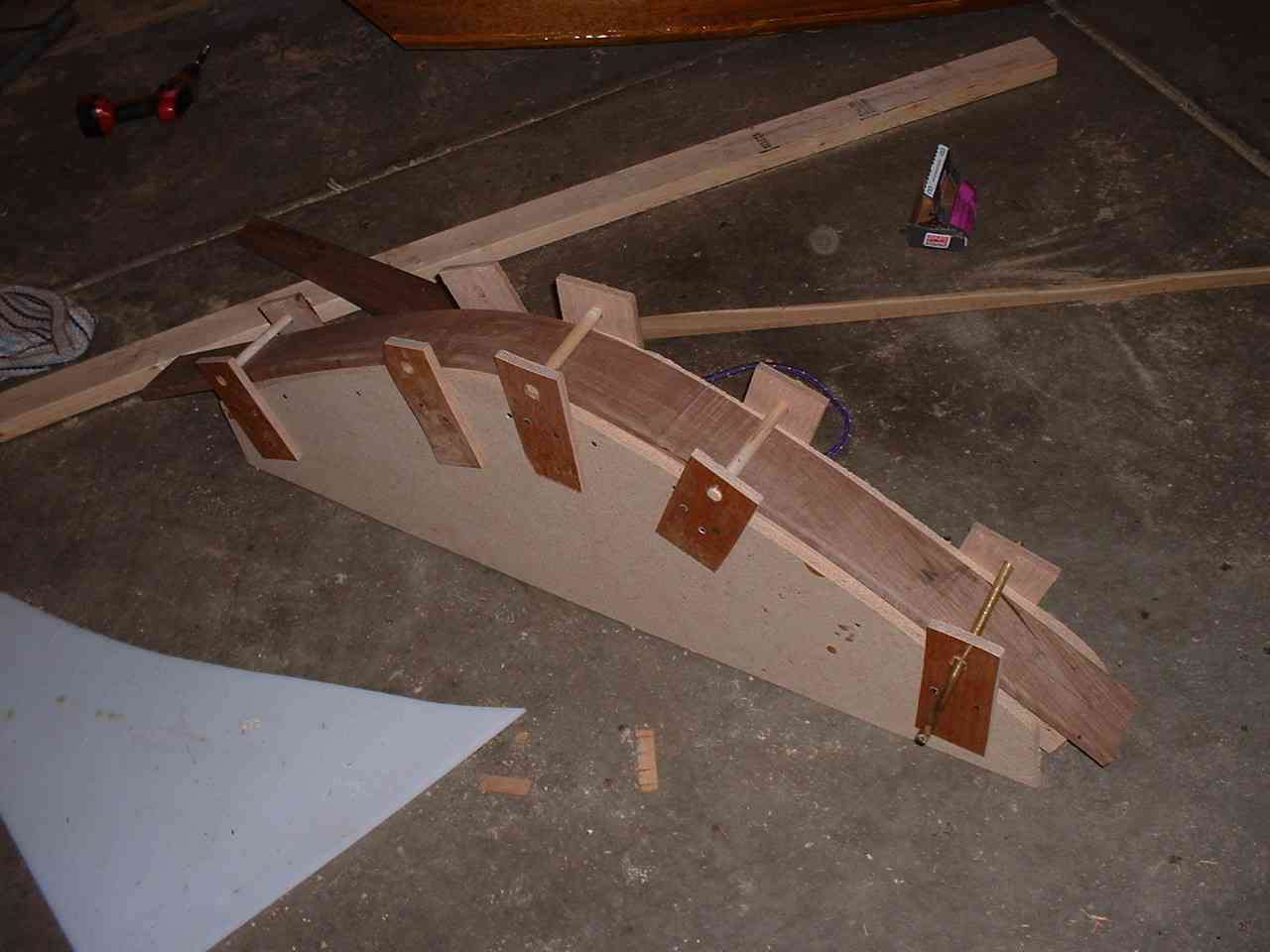

Before putting any wood in the steam box, you need to make a form that will provide a surface about which you will bend the wood. The form should also provide a means of easily holding the wood in-place. First, the outer contour of the form should be in the shape of a spline, since this is the shape that a bent piece of wood will naturally take. To make a spline curve, place nails at points on a curve that you desire to approximate with your work-piece. Next take a very thin strip of wood (spline or batten) and bend it around the nails. By scribing a line along a batten bent in this manner, you will insure that you have a "fair" curve to which your work-piece will conform. After constructing the basic form, you need to provide a means of clamping your work-piece to the form. I used dowels held by plywood scraps as shown below, so that I could quickly secure the work-piece as I bent it around the form. The piece should remain clamped for 24 hours. When removed, it will spring-back slightly but will hold the basic shape. Remember to add a small amount of additional curvature to your forms to compensate for spring-back.

Steam-bent black walnut leg-brace on the form.

Form for anchor support.

Tips:

Use air-dried hardwood if possible. Kiln dried wood has a greater tendency to check.

Use straight grained, defect free wood, or you run a serious risk of a split

Glue-down "raised hairs" if any pop-up.

Remember, steaming heats-up the water already present in the wood, it adds very little water to the wood.

Don't seal the steam box tight, allow some steam to escape, I stuffed towels in the ends of the box. This also keeps pressure from building up. Steam under pressure is very dangerous, so don't overlook this important point.

Consider using leather gloves and wear a long sleeve shirt when removing wood from the steam box to protect yourself from scalds.

For more information see the rec.woodworking Steambending FAQ

Copyright © 2003, David B. Doman PhD, All rights reserved.