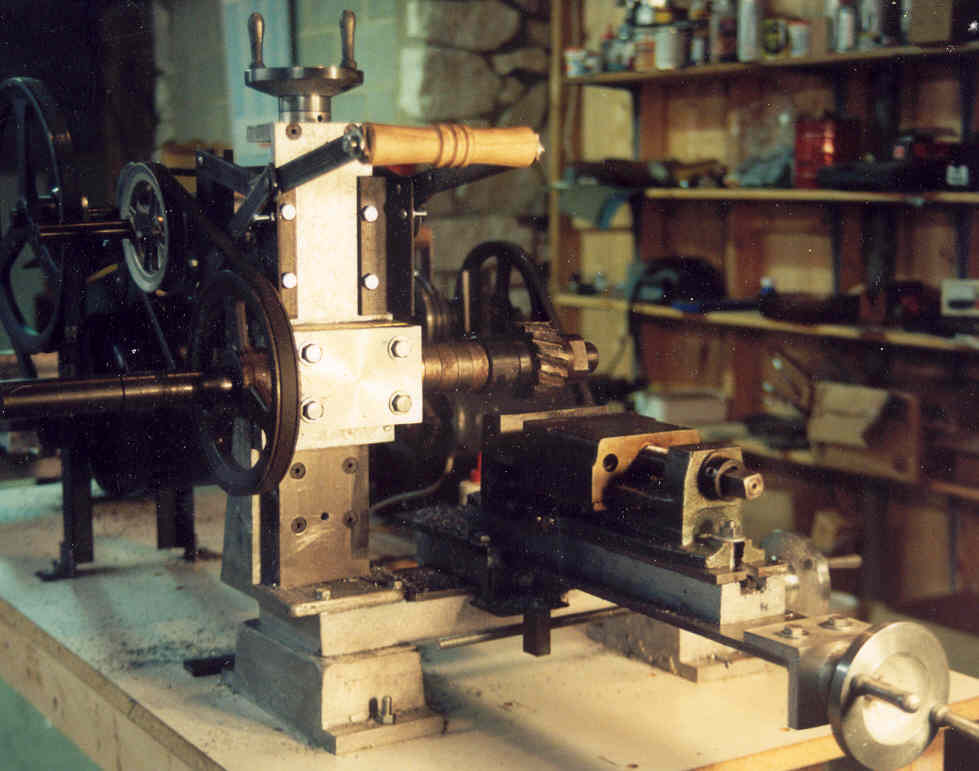

Gingery Milling Machine

After tackling the lathe project and being quite weary of filing and scraping, I decided that I would build the Gingery milling machine to make life a little easier. After building the lathe, the milling machine was not all that difficult. Nevertheless it did take a fair amount of time (~ 4 months of evenings / weekends). Having the lathe certainly helps. I did manage to obtain the shaft of a horizontal milling machine along with a wide variety of spacers through sheer luck on a trip to Mendelson's Liquidation Outlet in Dayton OH. Mendelson's is one of the largest surplus stores in the world (go to the third floor for a real adventure). I also picked up a number of used cutters while I was there that were reasonably sharp. I also bought a milling machine vice that mounts on the cross-slide. The milling machine performs quite well when using single point cutting tools like fly-cutters and boring bars. Multipoint horizontal milling cutters have a tendency to rumble and sometimes chatter. You have to take shallow cuts to get the job done. My overall take on the machine is the same as the lathe, built it primarily for the experience. The machine is usable if you are not in a hurry, although the vice does speed things up some.

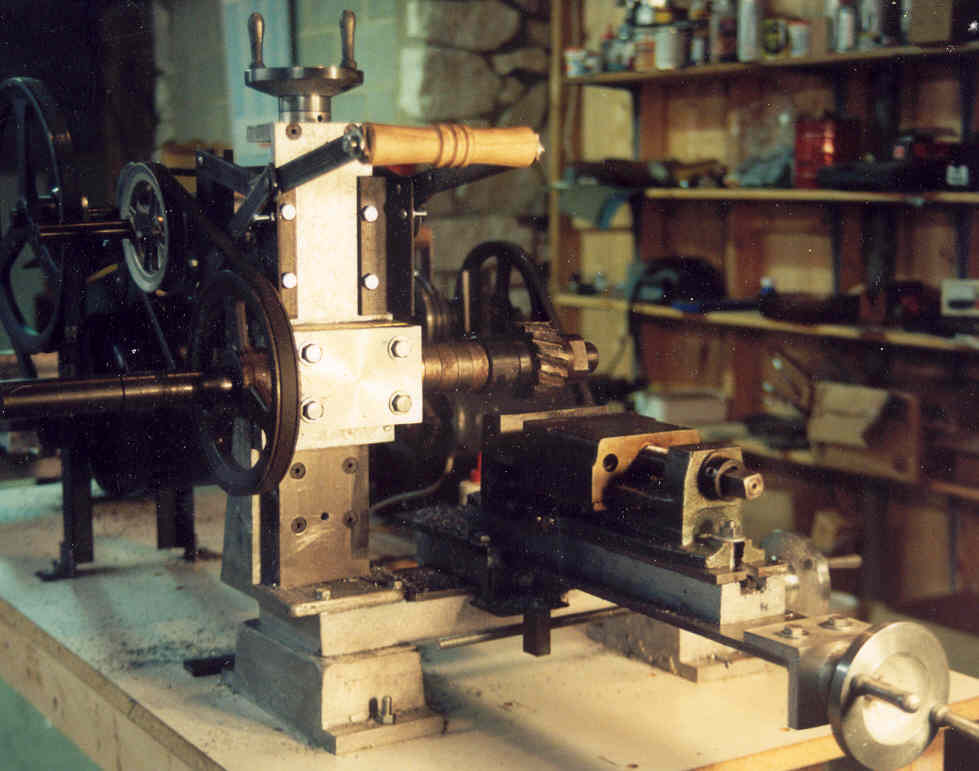

Wooden patterns used for the milling machine. Note the pattern in the middle for casting multiple handles simultaneously. The mill requires some split patterns like the one for the vertical slide. The vertical slide pattern consists of the two parts in the upper left-hand corner. When the sand mold is split, on part stays on the bottom (drag) and the other part stays in the top (cope). The patterns are removed and the cope is placed on the drag and metal is poured into a sprue hole.

Copyright © 2003, David B. Doman PhD, All rights reserved.